The advent of dental 3D printing has revolutionized the production of clear aligners, offering unprecedented speed, precision, and customization. At SprintRay, we are leading this transformation by providing cutting-edge 3D printing solutions that empower dental professionals to deliver high-quality, patient-specific aligners efficiently and cost-effectively.

The Digital Workflow

Clear aligner production begins with capturing a digital impression of the patient's dentition using an intraoral scanner. This digital scan is then imported into orthodontic CAD software, where the desired tooth movements are planned in incremental stages. Each stage requires a unique aligner, which traditionally would involve creating multiple physical molds through a labor-intensive process.

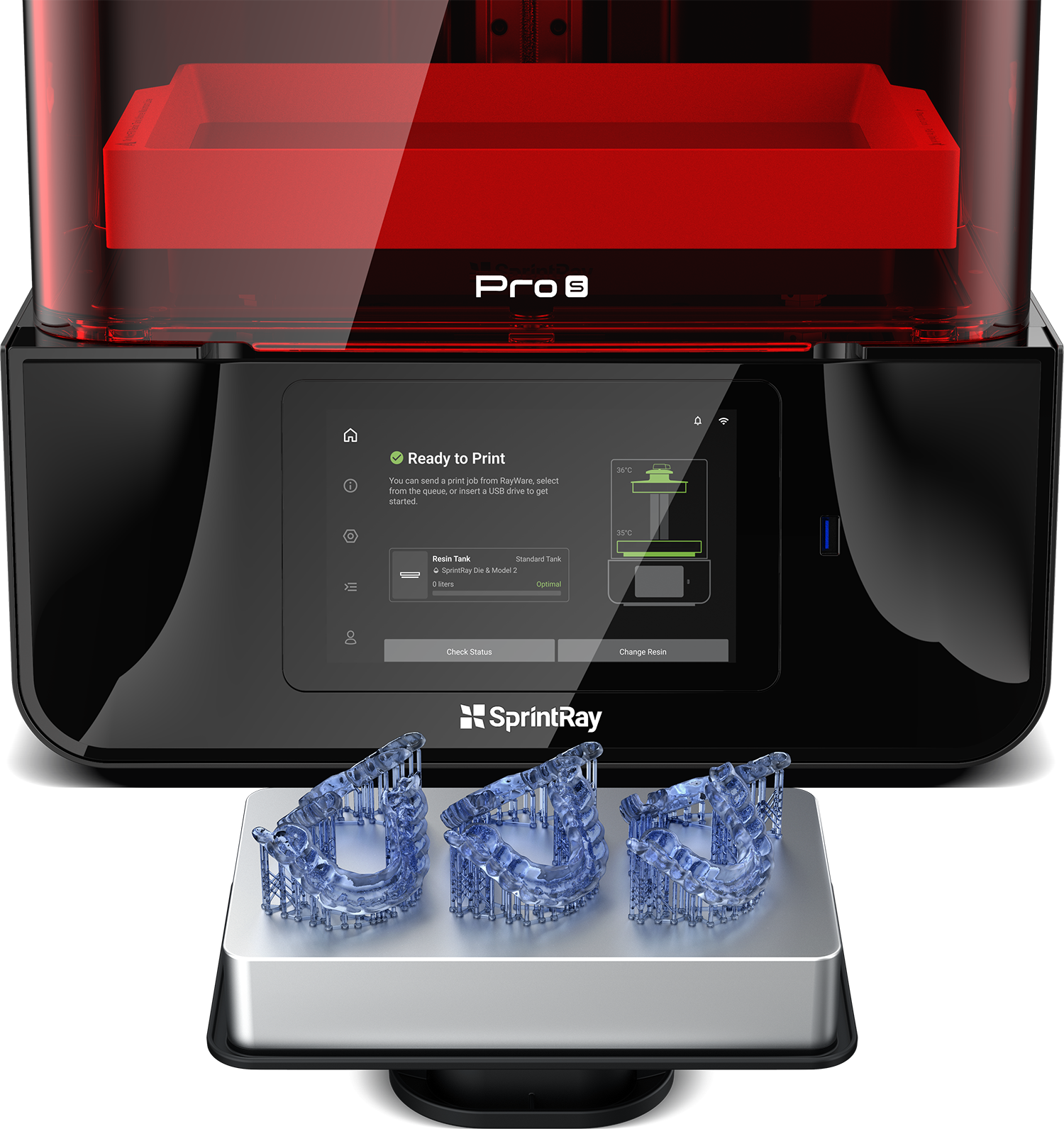

With SprintRay's 3D printing technology, this workflow is streamlined. The digital models for each stage are directly printed using our high-precision 3D printers, such as the SprintRay Pro S. This eliminates the need for manual mold-making, significantly reducing production time and labor costs.

Speed and Efficiency

One of the most significant advantages of using 3D printers for clear aligner production is the speed. Traditional methods can take weeks to produce a complete set of aligners. In contrast, SprintRay's 3D printers can produce a full platform of dental arches in approximately 25 minutes. This rapid turnaround enables dental practices to offer same-day aligner services, enhancing patient satisfaction and practice efficiency.

Customization and Precision

Clear aligners must be highly customized to fit each patient's unique dental anatomy. 3D printing excels in this area, allowing for the production of highly accurate and personalized aligners. SprintRay's printers offer exceptional dimensional accuracy, ensuring that each aligner fits perfectly and functions effectively. This level of precision is crucial for the success of orthodontic treatments, as even minor deviations can affect the outcome.

Cost-Effectiveness

By bringing aligner production in-house, dental practices can significantly reduce costs associated with outsourcing to external labs. The materials used in 3D printing are also more cost-effective compared to traditional methods. For example, producing a set of aligners with SprintRay's system can cost just a few dollars in materials, compared to much higher lab fees.

Versatility and Integration

SprintRay's 3D printing ecosystem is designed to integrate seamlessly into existing dental workflows. Our printers are compatible with various digital scanning and design software, making it easy to incorporate 3D printing into your practice. Additionally, the versatility of our printers means they can be used for a wide range of dental applications beyond clear aligners, including surgical guides, night guards, and retainers.

Conclusion

The role of dental 3D printers in clear aligner production cannot be overstated. By offering rapid, precise, and cost-effective solutions, SprintRay's 3D printing technology is transforming how dental professionals approach orthodontic treatments. Embrace the future of digital dentistry with SprintRay and provide your patients with the high-quality, customized care they deserve.